AAA Metals is a turnkey metal solutions provider offering a broad range of metal-related services, including material sourcing, conversion, finishing, and delivery. Our team specializes in converting raw metal material into ready-to-use products. In addition to cutting, shearing, and sawing the metal to size, we also offer a wide range of value-added services—such as centerless grinding—to ensure the material we deliver meets the outlined project specifications.

Overview of Centerless Grinding

Centerless grinding is an outer or outside diameter (OD) grinding process used in the manufacture of cylindrical and other rounded parts, such as rods and rollers. Compared to conventional grinding methods, it allows for easier and faster production operations as it does not require the use of work holders.

How Does Centerless Grinding Work?

A centerless grinding setup consists of three key components—a grinding wheel, a regulating wheel, and an angled workpiece support—with the support lying between the wheels. These components play the following roles:

- The grinding wheel applies force to move the workpiece against the support and into the regulating wheel.

- The regulating wheel determines the rotational speed of the workpiece. In through-feed grinding operations, a slight tilt of this component allows the workpiece to move through and out of the grinder.

The workpiece support creates a stable space for the workpiece to rest during the grinding operation. It also raises the centerline of the workpiece above those of the grinding and regulating wheels to facilitate successful centerless grinding operations.

Different Types

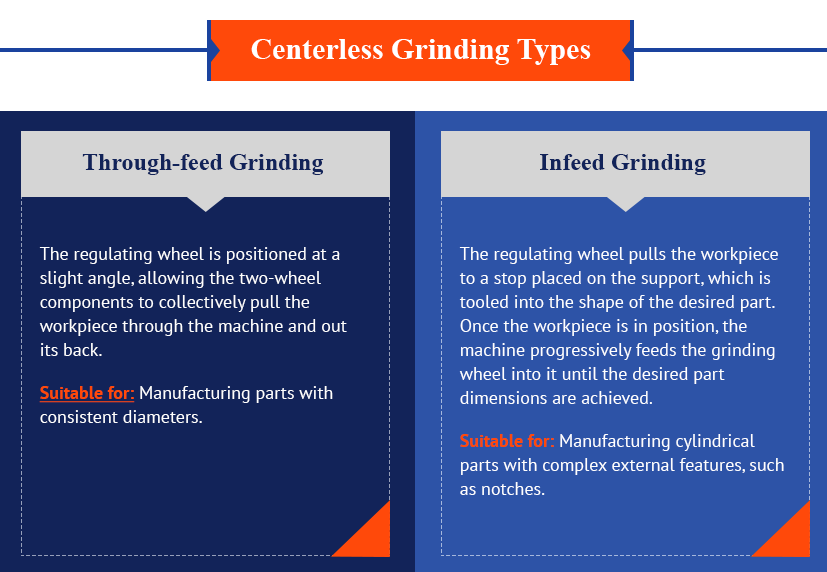

Industry professionals employ two types of centerless grinding depending on the part and production requirements: through-feed grinding and infeed grinding.

- As stated previously, in through-feed grinding, the regulating wheel is positioned at a slight angle, allowing the two-wheel components to collectively pull the workpiece through the machine and out its back. This method is suitable for manufacturing parts with consistent diameters.

- In infeed grinding, the regulating wheel pulls the workpiece to a stop placed on the support, which is tooled into the shape of the desired part. Once the workpiece is in position, the machine progressively feeds the grinding wheel into it until the desired part dimensions are achieved. This method is suitable for manufacturing cylindrical parts with complex external features, such as notches.

Advantages

Compared to other grinding methods, centerless grinding offers several advantages, including:

- Faster operations. It eliminates the need for work holding the workpiece, machine operators spend less time preparing the parts and machines. This reduces the overall production time, allowing them to finish pieces quicker and perform more operations per day.

- Greater workpiece support. The centerless grinding machine setup supports the workpiece for most—if not all—of its length. This process quality reduces the risk of part deformation or damage due to unstable or irregular forces acting on the workpiece.

- Higher precision. Compared to the cylindrical grinding process, this process makes diametral rather than radial adjustments to the wheels. This quality cuts potential infeed errors in half, allowing for the manufacture of more precise parts.

Our Centerless Grinding Services

At AAA Metals, our centerless grinding services facilitate the delivery of metal products that are ready for use in a wide range of customer projects. The metals we can process include:

- Aluminum

- Brass

- Bronze

- Copper

- High-temperature alloys

- Nickel alloy

- Stainless steel

- Titanium

We also offer other value-added services, such as:

- Bending

- Boring

- Drilling

- Forming

- Heat treating

- Polishing

- Rolling and Welding

- Sandblasting

- Stamping

Why Choose AAA Metals?

For over 40 years, AAA Metals has served as a supplier of high-quality metal parts and components. By employing a variety of fabrication and finishing services, such as centerless grinding, we deliver metal solutions that meet our customers’ needs. For more information about our centerless grinding services and how they can benefit your next project, contact us or request a quote today.