Metal polishing smooths the surfaces of fabricated metal pieces such as sheets, angles, and pipes, often providing the final finish before parts or materials go to their end use. Polishing stainless steel is highly beneficial, as it noticeably improves its resistance to damage caused by corrosion, environmental factors, wear, and impacts.

Stainless steel can be more challenging to polish than some other metals, but experienced metal polishers can achieve smooth finishes without blemishes or damage. AAA Metals specializes in polishing a variety of stainless steel pieces, such as:

- Linear pieces

- Pipe & Round Tube

- Square & Rectangular Tube

- Bars Round & Flat

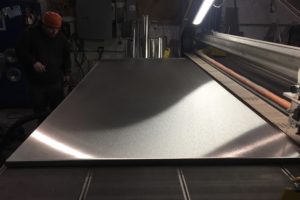

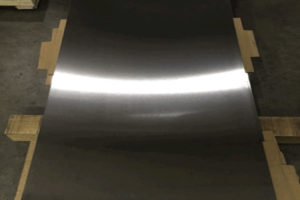

- Sheet

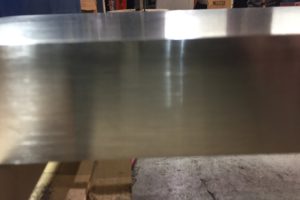

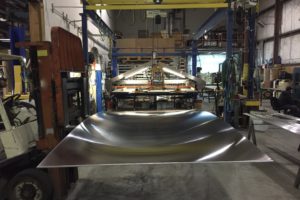

- Plates

- Angle

In addition to polishing, we offer end-to-end solutions for our clients. As both a fabricator and distributor, our team can convert raw materials into manufactured pieces, finish them, and deliver the order to your warehouse or distribution center.

For more details about the high quality stainless steel polishing services contact us directly or request a quote.

Understanding Stainless Steel Polishing

Once metal components have been machined, polishing is a critical finishing step for a variety of parts and components to improve the aesthetic appearance of the finished product. It also has several functional benefits, including:

- Lowering the risk of corrosion from oxidation

- Reducing contamination risks by eliminating cracks or crevices where bacteria and other harmful contaminants might gather

- Improving the service life of stainless steel components and surfaces

The Stainless Steel Polishing Process

The stainless steel polishing process contains between three and seven distinct stages to reach an ideal finish. Many of these stages involve using mechanical abrasive media—such as Alumina, Zirconia and Ceramics in the process of surface conditioning.

The requested finishing standard impacts the number of stages involved in the polishing process. Operators can use abrasives ranging in grit strength from 50-3,000 to gradually increase the smoothness of the finish without damaging the product. The No. 8 finish—one of the highest finishes that provides a mirror-like smoothness—requires abrasive alumina powder.

Stainless Steel Characteristics and Properties to Consider

Stainless steel is an ideal metal for a broad range of products and components, but it can be a difficult material to polish. This challenge is due in large part to two of the predominant characteristics of the metal:

Work hardening. Stainless steel develops an increased hardness the longer stress is applied to the surface—this is known as work hardening. This means polishing has to be fast and precise in order to complete the job before the metal’s condition changes and the abrasive agent no longer becomes appropriate. Expert metal polishing operators have processes in place to move quickly from step to step—or from grit to grit—without overworking the metal.

- Passivity. The passivity properties of stainless steel also require fast polishing speeds. The top layer of stainless steel oxidizes to keep corrosion and rust at bay. While abrasive polishing cuts through that layer, it is quickly replaced by a new layer of oxidized steel. The hardness of the new layer can disrupt the polishing process if operators aren’t moving fast enough.

Different grades of stainless steel can also simplify or increase the complexity of the polishing process. 304 is a basic type of stainless steel and one of the simplest to polish. 430, on the other hand, develops a hard oxidized surface layer and is more difficult to polish. - HRAP (Hot Rolled Annealed & Pickled) Steel Mill Process

The term “Pickled” means that the material has been subjected to an acid solution that has been specifically developed to remove the high temperature oxides that appear on the surface after annealing.

The Different Types of Finishes

A variety of finish types can be applied to most stainless steel. The different types are measured on a scale ranging from 0-10:

- #0 – This finish is typically used for thicker hot-rolled plates. It lets the metal anneal (slowly cool) to form a rough finish.

- #1 – The #1 finish is also for thicker hot-rolled plates. The surface is passivated, or covered by a thin inert layer.

- #2 –The #2 finish can be divided into multiple subcategories.

- #2D – Annealed, pickled, and passivated

- #2B – Finished with #2D metal and then passed through polishing rollers

- #2A – Finished with #2B metal, then brightly annealed again in an oxygen-free environment

- #3 – This finish uses coarse mechanical abrasion. It produces a surface finish with coarse, uniform parallel lines.

The remaining finish categories are described by the finish’s end result, rather than a specific methodology.

- #4 – This finish is similar to #3 but features slightly higher polish and reflectivity. It is commonly used in commercial and visible equipment.

- #5 – Satin

- #6 – Satin (Scotch-Brite™)

- #7 – Reflective (but not clear)

- #8 – Mirrored

- #9 – Ultra-mirrored with a bead-blasted surface

- #10 – Electropolished and heat-colored

AAA Metals specializes in producing #3, #4, and #6 finishes, as well as Scotch-Brite finishes. Scotch-Brite finishes smooth a surface down to 20 Ra. Scotch-Brite metal finishing wheels and processes can achieve brushed, mill, and satin finishes.

Polishing Processes

While almost all polishing processes involve mechanical abrasion, there are a variety of different processes and tools that work on different types and shapes of metal. The most common polishing processes include:

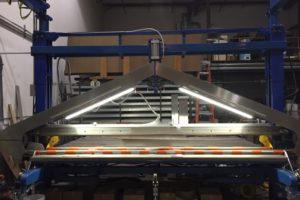

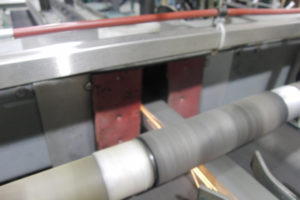

Belt Sanding

Belt sanding tools—or belt grinders—mechanically rotate a belt of gritted material to abrade the surface of stainless steel. The belts can have different levels of grit, including rough or low grit levels for the beginning stages of the process and fine or high grit levels for ending processes. The belts also come in different widths to handle different workpiece sizes.

Edge Polishing

When the edges of stainless steel pieces need to be polished, sufficient pressure needs to be applied to thoroughly polish edges in order to mitigate corrosion and contamination risks at high-contact points.

Face Polishing

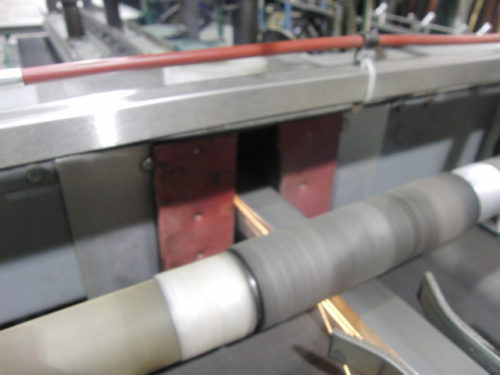

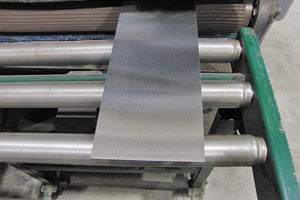

Polishing belts of zirconia / ceramic abrade polish stainless steel surfaces. These machines use different polishing grits that an operator may choose from.

Grinding

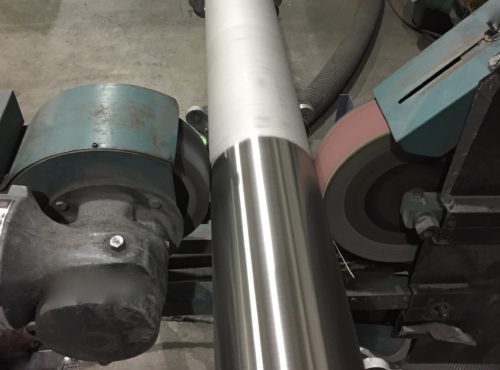

Grinding is one of the most common metal polishing processes. Various types of grinding machines can finish different shapes of metal ranging from plates to pipes. While grinding is typically considered to be a rougher, separate category of metal finishing than polishing, it can erase surface-level imperfections and is often used during the beginning stages of polishing.

Material Forms

Many of the processes listed above are specifically matched with different material forms which need to be ground and polished to match the standards of the industry that will use them. Some of the most common stainless forms include:

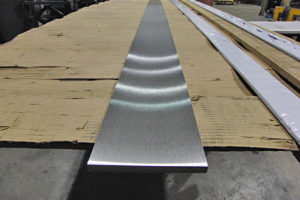

- Angles. These pieces are polished for a clean outside appearance for manufacturing and architectural applications. The angles need to stay precise and unmodified for exact measurement and placement. Often, the material is rolled to a HRAP finish and then polished to a #4 finish.

- Bars. Round bars often need a #4 or #6 finish for industrial and manufacturing purposes. Square bars may be finished with a #3 finish and then smoothed to #4 or higher.

- Channels. Channels require relatively smooth external and internal surfaces, especially when intended for use in industrial equipment and conveyance systems.

- Plates. Plates can be finished for a variety of functional purposes at a lower finish type. A higher luster finish can be achieved for applications requiring pleasing aesthetics using Scotch-Brite equipment.

- Sheets. Light and heavy gauge is used in almost every industry. Polishing makes sheets aesthetically pleasing, more sanitary, and easier to inspect.

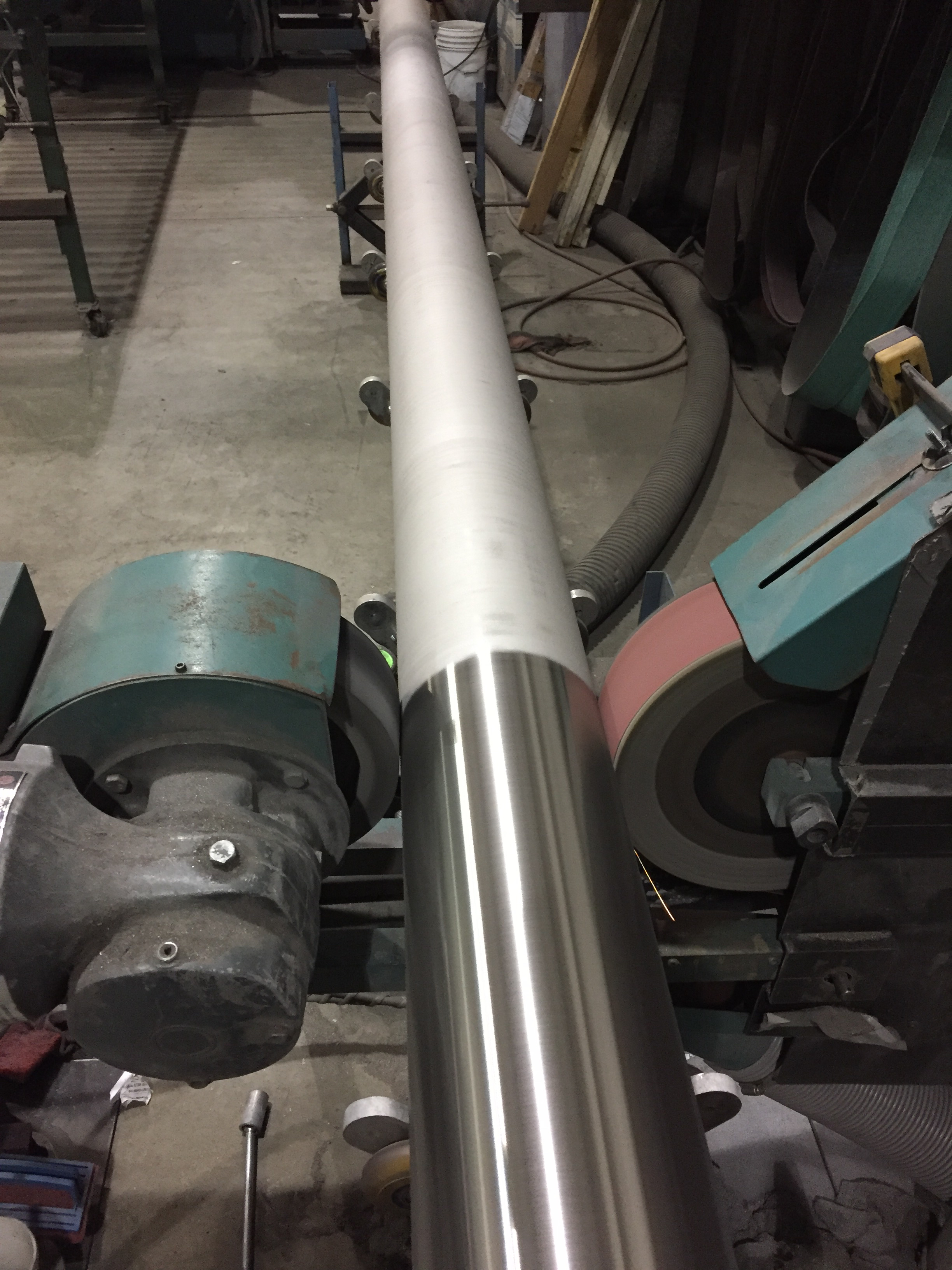

- Tubing & Pipe forms need to be polished to reduce the risk of external and internal contamination. Corrosion is more likely to form in rough internal surfaces where the fluid can wear past oxidized surface layers over time.

Common Applications and Industries

Stainless steel parts can be found in every industry as part of industrial equipment, architecture, and more. AAA Metals currently serves the following industries:

- Aerospace

- Architectural

- Biotech

- Chemical

- Fabrication

- Food Process

- Marine

- Mechanical

- Packaging

- Pharmaceutical

- Railing

- Retail

- Vacuum

- Welding

AAA Metals specializes in stainless steel polishing for consumables, discs, forgings, pipes and tubing, rings, and pumps across all industries.

High-Quality Stainless Steel Polishing Services at AAA Metals

For over three decades, AAA Metals Company has been an industry leader in stainless steel polishing, with full in-house capabilities to carry out belt sanding, grinding, face, edge, and OD polishing. Our advanced equipment includes multi-head machines as well as belt sanders, with ceramic, zirconia, and nylon impregnated polishing belts.

Polishing is available for parts sized up to 24 feet in length, up to 12 feet in width, 6 inches in height, and 12 inches in diameter, with weights up to 9,000 pounds. We are proud of the ability to handle part widths of 12 feet—a distinction few businesses in the New England area can claim.

Value-Added Services

Here is a summary of our most common stainless steel polishing services and capabilities:

- Waterjet cutting

- Precision shearing

- Precision sawing

- Laser cutting

- Pre-polished materials in stock

- Polished OD from 180 to 320 grit

- #3, #4, #6 and Scotch-Brite Finishes

- Sheet, plate, flat bar, square bar, square and rectangular tubing

- Angle, channel, I-shapes, T-shapes also polished (outside surfaces)

- Round bar up to 8”

- Round tube & pipe up to 10”

- Square bar & tube up to 10”

- Rectangular bar & tube up to 8” x 12”

- Plate up to 6” x 168” x 50’

In addition to premium polishing, we provide a full menu of value-added services including forming, bending, roll & weld, drilling, grinding, and other specialty processes. Typical turnaround times for polishing range from hours to weeks, and we handle prototype production up to volumes of hundreds of units. We pride ourselves on being a provider of turnkey solutions, so our value-added list of services also includes distribution and delivery.

For more details about the high-quality stainless steel polishing services or the other capabilities available, please see the table below or contact us directly.

Work hardening. Stainless steel develops an increased hardness the longer stress is applied to the surface—this is known as work hardening. This means polishing has to be fast and precise in order to complete the job before the metal’s condition changes and the abrasive agent no longer becomes appropriate. Expert metal polishing operators have processes in place to move quickly from step to step—or from grit to grit—without overworking the metal.

Work hardening. Stainless steel develops an increased hardness the longer stress is applied to the surface—this is known as work hardening. This means polishing has to be fast and precise in order to complete the job before the metal’s condition changes and the abrasive agent no longer becomes appropriate. Expert metal polishing operators have processes in place to move quickly from step to step—or from grit to grit—without overworking the metal.