AAA Metals is a dedicated provider of high quality stainless steel plates, bars, rings, discs, pipe, and tubing ranging from stock forms to polished, precision-cut pieces. We use a variety of fabrication techniques to shape, cut, and polish stainless steel plates to meet even the most stringent specifications. Our highly knowledgeable and experienced staff work with you to create custom stainless steel plates tailored to meet the needs of your application.

Stainless steel plate is highly valued for its strength and corrosion resistance, as well as its polished appearance. Thicker than sheet metal, metal plate provides a sturdy and reliable option for applications that require structural support and protection from the elements.

For more information about AAA Metals’ products and services, contact us directly or request a quote.

Properties and Benefits of Using Stainless Steel Plates

Stainless steel is an iron alloy that includes a minimum of 10.5% chromium. When exposed to oxygen, the chromium in the stainless steel oxidizes, creating a layer of chromium oxide that protects the underlying iron from rust-causing corrosive elements in the surrounding environment. In addition to iron and chromium, stainless steel may contain a variety of other metals. To meet the varying needs for stainless steel components, different grades have been formulated to enhance specific characteristics.

Common Grades of Stainless Steel

There are more than 200 different stainless steel grades on the market, from 304/304L to high-nickel grades 309/310 and then enhanced moly grade 316/316L. Whereas 321 contains a percentage of Titanium which has excellent resistance to oxidation and possesses good creep strength.

Although there are many grades to choose from, 304 and 316 grades are the most common for stainless steel plate.

. Grade 304 Stainless Steel

Grade 304 stainless steel is one of the least expensive stainless steel alloys available. It exhibits the high strength and corrosion resistance typical of stainless steel, and has the added benefit of high ductility, which makes it easy to shape and fabricate into durable components. As an austenitic steel, grade 304 has a higher amount of nickel than some other stainless steel alloys. This enhances both its formability and corrosion resistance, but the lower iron content means that 304 is less magnetic than other forms of steel, and it can’t be hardened using heat treatments.

. Grade 316 Stainless Steel

Grade 316 stainless steel shares many of the same characteristics of 304. It is austenitic, with a higher percentage of nickel. In addition, 316 contains molybdenum, for even greater corrosion resistance. This makes it particularly valuable for use in harsh outdoor and marine environments where the metal will be regularly exposed to highly corrosive elements.

In addition to its strength and corrosion resistance, 316 exhibits higher temperature resistance with low creep, and excellent formability. Whereas 316L has a low carbon content makes it especially good for welding.

Stainless Steel Plate Industrial Applications

With excellent corrosion resistance and high tensile strength, stainless steel plate has become a mainstay for industrial applications, including:

- Food and beverage processing

- Heat exchangers

- Chemical and pharmaceutical manufacturing

- Industrial machinery and conveyors

- Architectural equipment

- Marine and outdoor applications

Our Stainless Steel Plate Cutting & Polishing Capabilities

At AAA Metals, we are pleased to offer a comprehensive range of metal fabrication services for cutting, shaping, and polishing stainless steel plate. We offer everything from raw bars and stock to precision-cut and polished stainless steel plate. With more than 40 years of experience, we have established expertise in numerous fabrication techniques, including:

- Stainless steel polishing. Metal plate polishing ensures a smooth, flawless surface for optimal corrosion resistance.

- Precision shearing. Our precision shearing allows us to create stainless steel plates of varying thicknesses.

- Precision sawing. AAA uses state-of-the-art precision sawing equipment to ensure that even the thickest plate is cut to exacting specifications.

- Waterjet cutting. For extremely thick plate, we offer waterjet cutting to ensure accurate cuts without heat warping.

- Laser cutting. Laser cutting is available for highly detailed cutting, etching, and engraving.

- Value-added services. In addition to the above fabrication services, AAA offers a range of value added services including rolling, forming, welding, grinding, stamping, drilling, boring, and heat treating.

. Case Study: Polished Grade 316 Stainless Steel Vacuum Chamber End Plate

. Case Study: Polished Grade 316 Stainless Steel Vacuum Chamber End Plate

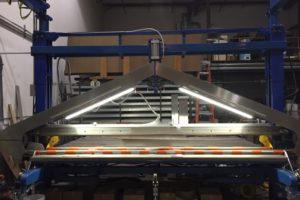

One of our stainless steel plate projects offers an excellent example of our stainless steel plate fabrication capabilities. We used our custom-engineered plate polisher to grind and polish two massive 6,000-pound end pieces for a stainless steel vacuum chamber. The piece was made of 2.5-inch thick 316 stainless steel and measured 110 inches in diameter, with precision cutouts and an oblong tail.

Our challenge was to grind and polish the pieces to an ANSI #4 (Ra 32) finish without rounding the edges. The customer was exceptionally pleased with the speed, precision, and cost of our services.

Contact Us for Your Stainless Steel Plate Needs!

At AAA Metals, we are committed to providing you with the best stainless steel plate fabrication services in the industry. With over four decades of experience and an extensive portfolio of metal manufacturing equipment and services, we are capable of handling both standard and custom projects with the utmost speed and efficiency. To learn more about AAA Metals’ stainless steel plate products and services, contact us today or request a quote.

. Case Study: Polished Grade 316 Stainless Steel Vacuum Chamber End Plate

. Case Study: Polished Grade 316 Stainless Steel Vacuum Chamber End Plate