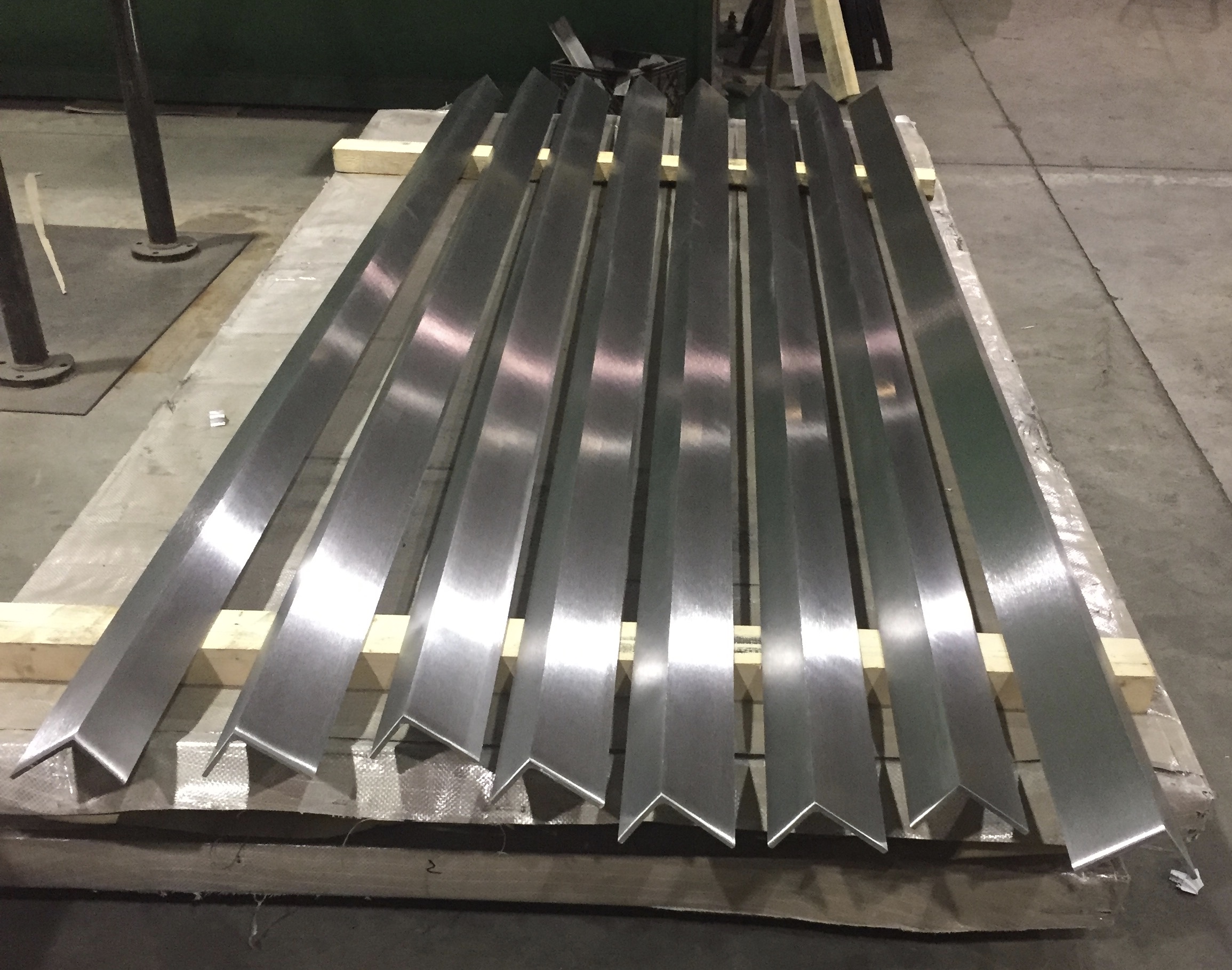

AAA Metals is a premier distributor of stainless steel, nickel, titanium, and hard-to-find metal alloys. We provide a range of quality metal components, from stock forms to precision cut and polished pieces. One of our core product offerings is stainless steel angles.

Stainless steel angles are used by manufacturers in a wide range of applications. Equipped with over 40 years of metal distribution experience, our expert team can shape and polish stainless steel angles to meet nearly any specification.

Common Stainless Steel Angle Grades

Stainless steel angles are available in a variety of grades, each of which offers distinct characteristics that make it suitable for particular applications. Two of the most commonly used grades are 304/304L and 316/316L, both of which demonstrate excellent strength and corrosion resistance.

. 304/304L

304 is a highly versatile stainless steel. Similar to most other stainless steels, it demonstrates excellent strength and corrosion resistance. However, it is much more affordable than many of the other grades. Additionally, it offers superior ductility and formability due to its higher nickel content and worse magnetic properties due to its lower iron content. While it can easily be formed and welded, it cannot be hardened using heat treatments.

304L is a low-carbon variation of 304. This difference in composition makes it a little easier to weld but a little less strong.

Typical industrial applications for 304/304L components include:

- Chemical processing and handling equipment

- Crude and refined oil processing equipment

- Food and beverage processing and handling equipment

- Hospital equipment

- Welded structures

. 316/316L

316 has many of the same characteristics as 304. However, it has a higher molybdenum content, which gives it greater corrosion and temperature resistance. This quality makes it highly suitable for use in outdoor and harsh environments where exposure to corrosive compounds is expected.

316L is a low-carbon variation of 316. This difference in composition slightly increases its weldability and slightly decreases its tensile and yield strength.

Typical applications for 316/316L components include:

- Aircraft parts

- Chemical processing equipment

- Food preparation equipment

- Medical instruments

- Oil rig pumps

- Paper and pump processing equipment

- Pharmaceutical manufacturing equipment

Stainless Steel Angle Supplier

As an experienced stainless steel converting and polishing company, we serve as a one-stop shop for all stainless steel angle needs. From sourcing raw steel from reputable suppliers to carefully cutting, grinding, and polishing it to spec, we ensure you receive quality components that fully meet your needs.

Our stainless steel angle capabilities include:

- Material: 304/304L, 309, 310, 316/316L, 317/317L, and other grades formed from plate

- Size: 3/4″ x 3/4″ x 1/8″ to 4″ x 4″ x 1/2″

- Type: Equal and Unequal Leg

- Finish: HRAP (heat rolled, annealed and pickled) and polished outside faces and edges

Polished angles are used for manufacturing and architectural applications where appearance is critical. Generally, we roll the raw material to an HRAP finish and then polish it to a #4 finish. Check out our stainless steel polishing page to learn more about our polishing capabilities.

Contact Us for Your Stainless Steel Angle Needs!

Contact Us for Your Stainless Steel Angle Needs!

If you’re looking for quality stainless steel angles, AAA Metals has got you covered! For more information on our angle offerings, contact us today. To discuss your requirements with one of our team members, request a quote.

Contact Us for Your Stainless Steel Angle Needs!

Contact Us for Your Stainless Steel Angle Needs!