To support our turnkey solutions for metal products, AAA Metals offers precision metal laser cutting services. Some of the typical products that we’ve applied laser cutting to include aircraft engines, cleanrooms, consumables, discs, forgings, pipes, pumps, rings, and tubing.

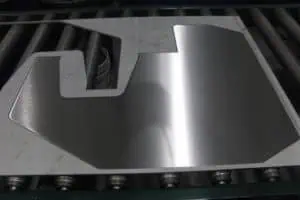

Our laser cutting services delivers ultra-precise cuts, edges and holes on a variety of metal materials. Combined with our stainless steel polishing and finishing services, these capabilities allow us to produce a wide range of custom shapes and designs from prototype to full volume production runs — with no minimum quantities.

Laser Fabrication Capabilities

In addition to cutting precision, laser cutting can offer additional benefits such as lower manufacturing costs, as the laser does not wear and no tooling is required. AAA Metals can laser cut components with the following capabilities/specifications:

- Up to 10,000 lb. metal workpieces

- Thicknesses up to 1 inch in stainless steel and up to 0.250 inches of aluminum

- Cutting tolerances of ±0.010 inches

90º Laser with Beveled Water Jet Edge

Materials for Laser Cutting

We have experience cutting custom shapes from a variety of metal materials in sheet and plate form, including:

- Aluminum

- Brass

- Copper

- Nickel alloy

- Stainless steel

- Titanium

Advantages of Laser Cutting

Laser cutting is a highly accurate process that uses a computer to direct the beam of a high-powered laser at the workpiece material. The term is slightly misleading in that the laser “melts” rather than “cuts” the metal, but the end result is a high-quality and precise edge. Laser cutting offers the following advantages over traditional metal fabrication methods:

- Elimination of machining and finishing operations (reducing the total cost of manufacturing)

- Lower energy usage and costs than plasma cutting

- Superior finished product durability

- Greater control and reliability during the cutting process

- Better workplace safety compared with other cutting methods

- Broader material and application versatility

- Higher precision and quality edges

- Lower chance of contamination due to no direct contact with the material

- Minimal equipment maintenance and replacement costs

- Reduced material wastage

Common Industrial Applications of Laser Cutting

Laser cutting finds application across a wide range of industries, including:

- Aerospace

- Architectural

- Biotechnology

- Chemical

- Food processing

- Marine

- Packaging

- Pharmaceutical

At AAA Metals Company, advanced laser metal cutting is a key part of our complete finishing service offering. To ensure your metal component meets the highest quality and integrity, components are subject to quality control including surface testing, dimensional testing, ultrasonic testing and visual inspection.

To further facilitate the delivery of a complete solution, our customers take advantage of our comprehensive range of value-added services on top of our stainless steel polishing capabilities, including:

- Bending

- Drilling

- Forming

- Grinding

- Heat treating

- Rolling

- Stamping

- Waterjet cutting

- Precision sawing

- Trepanning

- Welding

For more information about our laser cutting services and how they can benefit your next project, request a quote today.

- Laser cutting available for Stainless Steel in thickness up to 1 in.

- Laser cutting available for Aluminum in thicknesses up to .250 in. with cutting tolerances of .010 in